September 5, 2002

Bulletin #83

Table of contents:

Bulletin of the Month

The Basics of Production Ostrich Nutrition, Part 1

By: Fiona Benson, Blue Mountain International

Daryl Holle, Blue Mountain Feeds, Inc.

Our e-mail address

Subscribe – Unsubscribe information

Bulletin of the Month

The Basics of Production Ostrich Nutrition, Part 1

First Presented as Papers for the World Ostrich Congress 2002

Warsaw, Poland, September 26 to 29, 2002

INTRODUCTION:

The subject matter of our presentations has been requested to cover Nutrition of Ostrich Chicks and The Basics of Production Ostrich Nutrition. The two in fact go hand in hand as the basic principals apply to all production groups. Successful chick rearing starts with the breeders laying quality eggs with good nutrient transfer and currently this is where 99% of current chick rearing problems start.

Daryl Holle’s research has clearly identified the nutritional requirements for Ostrich and the Ostrich’s remarkable efficiency of feed utilisation when all things are right. It is this feed efficiency that enables Ostrich to be highly profitable and yet maintain the "clean and green" aspects of production that our consumer wishes to see. As will be demonstrated in this paper, contrary to popular belief, grazing birds in a domesticated environment can in fact have a serious impact on the overall health of the birds and compromise producer returns.

The objective of these two papers is to demonstrate the basic factors required to enable those producing ostrich and their support specialists to understand the factors that are most critical to success from a production nutritional viewpoint. This will include Feed Management, as this is an area that is little understood and the important role that it plays in production nutrition and the overall success of raising ostriches.

HISTORY:

Whilst Ostrich have been raised domestically in South Africa for around 150 years, it is only in the last decade that any work was started on their Nutritional Requirements and management systems to bring them in line with modern livestock production. The last decade has also been a time of rapid growth of the industry where birds have been traded across International boarders on a large scale. As a result there has been a tremendous amount of misinformation with the majority of those involved new to production livestock. Many have turned to South Africa for advise without recognising that South African agriculture, as a result of the political situation and sanctions, had fallen behind in technological development of livestock production.

Significant advances have been made in understanding of livestock production nutrition over the past 20 years in the US and Europe. Part of these new developments has brought about changes from defining nutritional adequacy. This has moved from defining nutritional adequacy as freedom from clinical deficiency signs as it has been found that nutritional essentiality has set its sights dangerously low. It can be likened to a producer who concentrates on a breakeven return when real profits are possible. [1]

With Ostrich at this time, most all we see show clinical signs of malnutrition, some cases very severe indeed and many birds demonstrating clinical unthriftiness, these symptoms have been virtually eliminated in other farmed species in countries with progressive agricultural practices. With Ostrich this situation is aggravated by the fact that few support specialists, both in South Africa and elsewhere have seen what we would class as a ‘healthy’ ostrich and this has resulted in the spread of misinformation and incorrect conclusions.

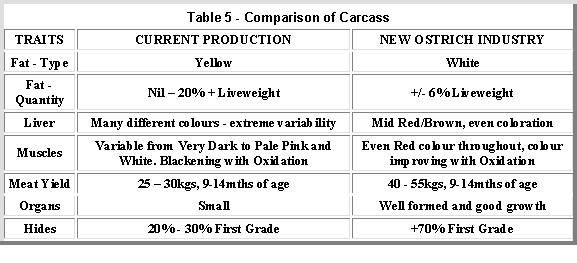

Most all processors of Ostrich at this time will report variable muscle development, variable fat quantity and quality (white fat, yellow fat) and variable condition of the different organs. The liver is a most important organ with many functions to perform:

“The liver filters the blood, metabolizes foreign exogenous and endogenous substances, and synthesizes bile, many enzymes and proteins for bodily functions, as well as for the formation of the yolk. It also has a role in many metabolic processes such as carbohydrate utilization and storage." [2]

In relation to Chick survivability, the fact that we currently experience the tremendous variation in liver conditions is a clear “clue” as to the current inadequacy of the rations and the inability of the hens to provide sufficient nutrient transfer. As can be seen in the above statement the liver is involved in the ‘formation of the yolk’. It is clear that if the liver is unable to function adequately, the hen is unable to provide adequate egg nutrient transfer. Ostrich are extremely sensitive in this regard and malnutrition is currently the primary reason for such variability in the condition of chicks at hatch.

|

Figures 1 and 2 are photos of egg follicles taken from hens at the same stage of the breeding season. Figure 1 come from a hen that was starving and had to draw on her egg follicles for nutrients for normal body maintenance. Figure 2 is from a hen that was producing well and broke her leg. |

|

| Figure 1: Egg Follicles, Starving Hen | Figure 2: Egg Follicles, Production Hen |

Figure 3: Yellow Liver Chick

Figures 3 and 4 are chicks from both ends of the spectrum with regards to condition at hatch. The chick in Figure 3 would have a tough time surviving since the liver is unable to function adequately to produce the bile required to break down the fats and aid proper digestion of the nutrients within the yolk sac.

Figure 4: Healthy Chick

Figure 4 on the other hand indicates a healthy chick, with a yolk sac that clearly demonstrates good bile production. [3]

These photographs clearly demonstrate the critical role that the Breeders play in Chick Nutrition. The basics of nutrition are the same throughout all the production groups.

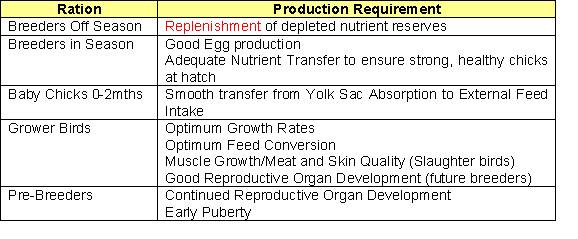

The differences come in the ‘production’ requirements of the different rations as shown in Table 1:

Table 1: Production Ration Requirements

Balanced Production Rations:

It is most important to understand with Ostrich their low daily intake of feed and the CHALLENGES this creates.

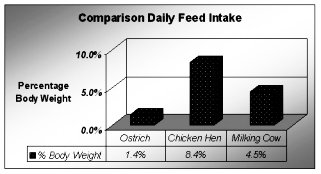

Figure 5: Daily Feed Intake Comparisons

Figure 5 is a simple comparison between Ostrich, Poultry and Dairy Cattle to demonstrate how little space there is in productive rations for Ostrich and why they respond like no other specie to good nutrition [4]. When reading this paper it is essential to read with an understanding of this extreme sensitivity of Ostrich to what may seem like minor changes in most other production livestock specie.

When studying the content of this paper it is also important to remember that:

Everything that passes through the mouth during the day CONTRIBUTES to the TOTAL DAILY NUTRIENT INTAKE and therefore influences the balance of the Overall Ration.

It is also important to know that a Balanced Ration must contain the following nutrients:

· Water

· Protein

· Energy

· Vitamins

· Minerals

The following factors to be balanced are not so easily understood by many nutritionists, producers and support specialists and these are the aspects that this paper will discuss:

| Nutrient Sources (Ingredients) | |

| Ratios Ingredient Type |

|

| -Forages, Grains, Protein, Fats, Vitamins and Minerals |

|

| Nutrient Ratios One to Another | |

| -Dependency of one nutrient to another |

|

| -Prevent interferences |

|

| Ratios of Organic to Inorganic | |

| Ratios of particle sizes |

Ingredient Type

A balanced production ration for ostrich must contain ingredients from the following types:

Forages

High Fibre, Medium Protein and Energy. Quality Lucerne is the most suitable forage for Ostrich. Using any other fibre source will result in reduced production.

All too often the word ‘roughage’ is used in a manner that indicates that it is fed ‘over and above’ the basic ration and simply there to ‘aid’ digestion. Remembering the very low daily feed intake of ostrich it is a challenge to pack all the required nutrients into a production ration, therefore the forage source must be highly digestible and contain the maximum nutrients possible.

Grains

High in Energy and low in Protein and Fibre. Grains utilised in Ostrich rations should be quality whole grain products, high in energy. High fibre grains such as Oats are not utilised well by Ostrich. Maize is the best grain and a production ration requires at least 50% of the GRAIN portion of the ration to be quality Maize, as Maize has certain characteristics that cannot be replaced by the other grains.

Protein Feeds

Ingredients that are high in Protein, Low in Fibre and Medium Energy. Dehulled Soyabean is the best protein source for ostrich with the right amino acid structure for Ostrich. [5]. Most other oilseed protein feeds carry certain difficulties and also lower levels of Protein and thus require higher inclusion levels that can cause certain difficulties in achieving the correct ratios of protein feeds, grains and forages in the ration.

Major, Minor and Trace Minerals

The highest grades of minerals have to be used as lower grades often contain many mineral contaminants that will interfere with other minerals in the rations. As Productive Ostrich rations are extremely dense, these interferences are more pronounced and have to be watched most carefully.

Vitamins and Additives

Vitamins are available from the major ingredients that are not subjected to heat treatment. ALL vitamins require additional supplementation from quality sources.

There have been many studies that have highlighted the tremendous variations in vitamin levels in crops in recent years. A study carried out by Cort W.M et al [6] is one such study.

Vitamins are the nutrients that regulate the biochemical reactions by which energy and protein are used for Health, Growth, Feed Conversion and Reproduction. Without vitamins these biochemical reactions WILL NOT OCCUR. [1]

Fat and Oil

The major ingredients contain a certain level of fat. Optimum production can be achieved when a level of animal fat is supplemented in the ration. [7]. If animal fat is used it must be from a pure source, in view of the implications now with BSE in poorly rendered fat sources as these can still contain some protein elements.

There are many different fats on the market for use in livestock production. Ensure the source is from a quality source and not recycled fats from supermarkets or restaurants. Ensure the fats do not have any other additives that could interfere with other nutrients in the rations.

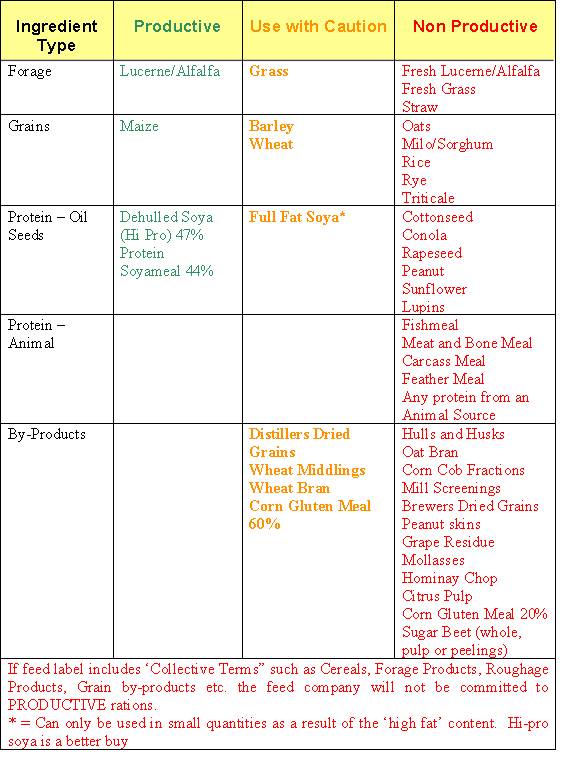

Table 2: Production Characteristics of Feedstuffs

Ratios of Ingredient Type

It is important to maintain a balance of ingredient type without an excess of any one type. This can influence a number of utilisation factors and the gut ph. This is particularly important with baby chicks in controlling bacteria growth.

To help understand the productive characteristics of different ingredients in ostrich, one can classify ingredients as:

-Productive – use within the normal ration

-Use with Caution – can have a positive influence at very controlled inclusion levels

-NON Productive and NO place in Ostrich Rations. (Table 2)

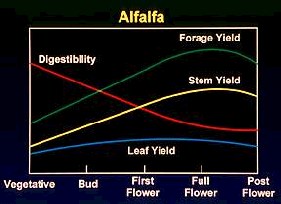

Figure 6: Lucerne/Alfalfa Digestibility/Maturity

It has been suggested that Wheat Bran can be used as a substitute for lucerne. This does not work as the type of fibre in Bran is from a grain source and not a forage source. Therefore the correct ratios of fibre sources are destroyed. Grain also has different characteristics in the digestion process. Productive ostrich rations must contain fibre from a quality forage source, including chick rations. There are many high grain ‘poultry’ type rations currently produced for ostrich, especially as starter rations and this is aggravating the chick mortality problem.

Lucerne needs to be 17% protein or above as this maintains the correct ratio of leaf to stem (Figure 6). Below that level there can be too high a proportion of stem, which is less digestible and lower in nutrient levels. [8].

Nutrient Ratios

When discussing energy values the NRC (National Research Council) book for poultry says:

"The TME procedure, however, has been subjected to criticism. TME determinations ASSUME that faecal metabolic and urinary endogenous energy excretions are constant, irrespective of feed intake. Data has been presented showing that, to the contrary, metabolic and endogenous energy excretions are influenced by amount and nature of materials passing through the gastrointestinal tract (Farrell 1981, Farrell et al. 1991, Tenesaca and Sell 1981, Hartel 1986).”

To interpret the above warning, what it is stating is that TME may not always be an accurate judgement of TRUE Energy in the feed, as it claims to be, depending on the combinations of feedstuffs used. This is an extremely important factor to remember and a very true statement in our opinion. It is a statement that applies to assessment of all nutrient utilisation and not confined to energy.

A ration may analyse with the correct levels of certain nutrients, but if those nutrients are from a source that the particular specie cannot utilise, then there will be deficiencies in the ration. For example, if one or more vitamins are deficient, NO increase in the other nutrients will overcome this deficiency and permit those functions to occur. [1] Today in other livestock it is widely recognised that these deficiencies do not have to approach clinical status before they compromise a Producer’s return. With Ostrich the clinical signs of nutritional deficiencies remain very prevalent.

Levels and Ratios of Amino Acids

Proteins are extremely complex compounds made up of a large number of amino acids. Non-Ruminants, such as Ostrich, are dependent upon feeds and feed ingredient combinations to supply the necessary amino acids in the proper amounts. Feeding a combination of ingredients to supply the proper levels of the required amino acids is necessary because energy sources such as cereal grains are deficient in certain essential amino acids. Each feed ingredient has its own set of inherent amino acid structuring called a ‘Profile’. It is important to closely consider the total profile of all ingredients used in an Ostrich feed diet so that it properly matches the “production” needs of the bird.

It is important to remember that the ‘total’ amino acid profile of the Ostrich diet still needs to be balanced to production requirements and most times that requires adding specific amino acids from a direct source through the premixes. This is one reason why it is an extremely dangerous practice to use one nutritionist's premix with another’s ration formulations. Production premixes are designed to work with ALL the ingredients in the ration and not in addition to.

The true protein determining factor is not whether a feed formula is 20% protein or 18% protein but rather, it is the amino acid profile of the formulas, as amino acids are the "building blocks" and foundation of protein. That is why on occasion an 18% protein feed can work as well or better than a 20% protein feed---because the amino acid profile is different between the two formulas. Amino Acid profiles change or vary according to the feedstuff ingredients used in a formula and another reason why it is so important never to substitute ingredients specified in a ration formula with other ingredients that are not specified in a feed formula.

|

Ratios of Organic to Inorganic

The major feed ingredients contain certain minerals in different proportions depending on plant type, local conditions and nutrients provided to the crop during the growing process. Additional mineral supplementation is also required and these are best added from inorganic sources. Animal Protein Products (APPs) provide a higher level of organic mineral sources and thus when included in a ration create an imbalance of organic to inorganic ratios. Fortunately APPs are no longer allowed in many regions and should never be used in Ostrich. Apart from the negative nutritional aspects, our greatest marketing tool is the health attributes of the meat. Producers have a duty to ensure that their rations do NOT contain any APPs, this is the only way to prevent feed companies from using them in animal feed rations in countries where APPs are permitted.

Another ingredient, when used in Ostrich rations, that interferes with the organic/inorganic ratios is Grass and/or maize silage. Grasses are very low in calcium and additional supplementation would need to be provided in the rations from inorganic sources. This is a double negative in producing productive rations as not only is the organic/inorganic ratio out of balance, the additional room required in the ration to make up the loss of calcium takes space in the ration required for productive ingredients that provide other essential nutrients.

Ratios of Particle Sizes

As referenced earlier there are many interrelationships between different nutrients. If one of these is provided in a form that can be absorbed into the blood stream quickly and another in a form that is absorbed slowly, then imbalances creating deficiencies and excesses will still occur, even if the levels sample correctly in the ration.

Another area where particle sizes are most important is the finished rations. If a ration is not pelleted it is most important that the finished ration contains all ingredients at a similar particle size to minimise the risks of the birds being selective in the feed intake. For example grains should be ground not included whole. Grazing or feeding silage creates significant challenges to achieve balanced intake of all nutrients. Grazing not only changes in nutrient values depending on the season and type of grazed material, it also varies considerably in moisture content making it even more difficult to achieve uniformity in daily intake. This will be discussed in the second paper.

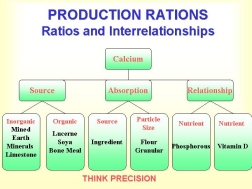

Practical Example

Calcium is an excellent nutrient to illustrate the principles discussed above. Figure 7 Using this example, the inorganic source for Calcium will generally be Limestone - there are however, many different grades of limestone. The lower grades have low levels of calcium and contain other mineral contaminants that will cause interferences with other minerals in the rations.

The major organic source is from Lucerne. Soyameal and Bone meal also supply a certain level of calcium. Bone Meal is NO longer allowed by many countries and as discussed earlier should NEVER be used if we wish to ensure the "CLEAN AND GREEN" attributes of Ostrich. When included as a source of calcium it has a very low absorption rate and results in very little of the calcium being utilised by the Ostrich.

Figure 7: Ratios and Interrelationships

As referenced particle size is important as this also affects the rate of absorption. It is common knowledge that the calcium/phosphorous ratio is critical. If however the calcium is from a source that is absorbed very slowly and the phosphorous from a source that is absorbed very quickly (for example) - they will not be in the digestive system together to work with each other - and deficiencies will occur. The ration will analyse correctly - but the birds will show symptoms of deficiency.

In order for the calcium and phosphorous to be utilised, the ration must contain adequate levels of vitamin D to carry the calcium and phosphorous into the blood stream. If the Calcium and phosphorous levels, sources and ratios are correct, but there is a shortage of Vitamin D – the birds will also show symptoms of deficiency.

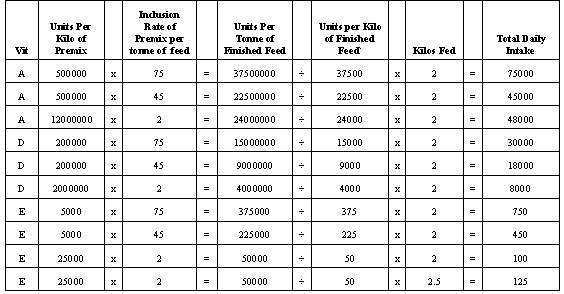

Calculating Vitamin and Mineral Levels in a Home Produced Ration

The most cost effective method of feeding the birds is generally home mixing – depending on the size of the operation. It is essential to know if the vitamins and minerals in the premix you are working with are supplying adequate levels of the vitamins and minerals.

The confusing part is that it is not only the amount stated on the label but also the INCLUSION level per tonne of complete mix that must be considered in assessing this.

Major minerals are usually listed in percent and should be guaranteed on the tag of the premix. Beware of maximum guaranteed values as the actual levels can be anything below. Trace minerals, if listed on the tag, are generally stated in parts per million (ppm). Fat soluble vitamins A, D and E are generally stated in International Units (iu) – per kilogram. The water-soluble vitamins are usually listed as milligrams per kilogram, (mg per kg). However, these are not standardised. The method of calculating the inclusion level in the finished ration is the same.

To calculate the inclusion Rate per Tonne of finished feed:

(Units per kilo of premix) X (inclusion rate) = (Units per ton of finished feed) Divided by (1000) = (Units per kilo in the finished feed)

To calculate the total fed per day:

(Units per Kilo in the Finished Feed) X (Number of Kilos Fed per Day) = (Total Daily intake of the particular vitamin or mineral)

Table 3 provides some examples of how to calculate the quantity per kilo and total daily intake. Note how the highest Units per Kilo of Premix result in the lowest Units per Tonne of Finished Feed. This is as a result of the very low inclusion rate per tonne of Finished Feed.

Table 3: Calculation of Vitamin Units per kg of Finished Feed

Warning

Over the years we at Blue Mountain receive a great many messages for help. There is an alarming trend that we need to report to you. During the last decade there have been a few details published on the perceived nutritional requirements of ostrich. There are many dangers in this. There is also a belief that anything published has been thoroughly researched and proven to work. This is not true in too many instances.

Our experience has also highlighted that when "copying" this information, errors have been made that in some cases has resulted in TOXIC levels of certain nutrients being used. With the lack of knowledge by those using these mistyped rations these errors are not being picked up. One example had the original Vitamin D as 2,500 IU/kg in the finished ration. The typo resulted in 25,000 IU/kg in the finished rations. Not only are these levels of Vitamin D toxic, such an error created severe problems with the relationship to other nutrients in the ration. Another error had Selenium at .300ppm per kg in the finished ration. The typo resulted in 300ppm per kilogram in the finished rations.

We have also been asked to comment on premixes where it is most difficult to determine exactly what is in the bag as the wording is not provided in a clearly defined manner. For example the ingredients listed are not clearly defined as units per kilogram, but rather units per pack, which may be 3.5kgs or 4.00kgs.

The only way to avoid this happening is for each and every producer to take the responsibility to understand exactly what they are feeding and if the information has been verified. These errors have caused much suffering to birds and also economic suffering to the producers.

We no longer publish nutrient levels as can be seen from this paper, there is so much more to a productive ration than basic nutrient levels. When copying, the risks of errors and misinterpretations are too great with the resultant bird suffering and financial hardship for producers.

CONCLUSION

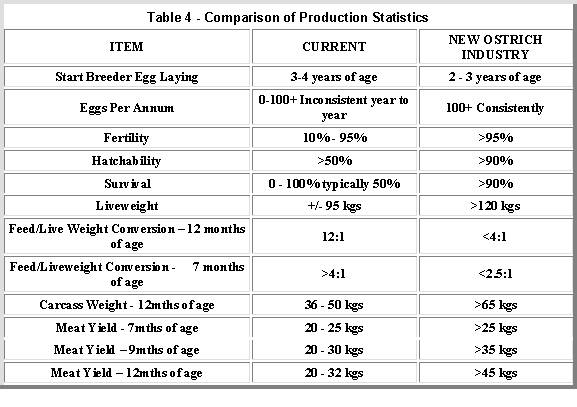

Achieving a balanced ration is the first step to successful Ostrich production to work towards achieving the production targets of The New Ostrich Industry (Tables 4 and 5). The next step is to ensure the feed is mixed correctly and fed correctly to maximise the benefits of Good Nutrition. We will discuss this in Part TWO of "The Basics of Production Ostrich Nutrition".

References:

[1] Bond P, Boren B, Campbell D, Williams S, Wilson J, Zimmerman C 2000 Optimum Vitamin Nutrition for Optimum Animal Health and Performance Nutrafacts Vol. 3 No. 2 Page 1

[2] Ratite Enclyclopedia

[3] Holle D 1999 Yellow Livers in Baby Chicks is Not Normal, Ratite Special Bulletin No. 40

[4] Holle D, 1995 Ratite Feeds and Feeding Page 1

[5] Cooper R.G, Benson F.V, 2000 Feed Mix Volume 8 No. 2 Page 25-26

[6] Cort W.M et al 1983. Vitamin E content of feedstuffs determined by high-performance liquid chromatographic fluorescent. J.Agri. Food chem.. 31:1330

[7] Cooper R.G, Benson F.V, Holle D, 2000 Fat as a Health Status Indicator in Ostriches, Feed Mix Volume 8, Number 3, 27-29

[8] Holle D, 2002 The Importance of Quality Alfalfa in Ostrich Formulas, Ostrich Nutrition E-Bulletin No. 77

To Be Continued In Part Two

Click to return to Contents Page

|

Contact Information:

If you have any Bulletin Topics you would like us to consider for publication in a future E-Bulletin, e-mail your information to

. We are always interested in hearing your ideas about the value of this E-Bulletin, or whether you have any problems viewing this document.

If you would like to discontinue your subscription to this E-Bulletin, or if you have additional e-mail addresses to add to our subscriber list, please visit the following page on our website and use the automated form to “subscribe” or “unsubscribe”: www.blue-mountain.net/feed/bulletin.htm

Also check out our web site at www.blue-mountain.net for feature articles addressing Ostrich Nutrition, Feeding Management, and Ostrich Farm Management.

Click to return to Contents Page

|

Blue Mountain Ostrich Nutrition E-Bulletin © September 2002

Return to Bulletin Menu