Blue Mountain

Commercial Ostrich Production

Presented at WOA Chile Conference 2003

Production Nutrition, Feed Management, Farm Management and Genetics

Fiona Benson and Daryl Holle

Introduction

During The 2nd South African Conference held in October 2002 a major processor made two very important statements.

- No Raw Material – No Industry

- In livestock terms the current level of Ostrich Production is miniscule and there are many markets that we cannot hope to access through lack of volume.

Other key statements we continually hear and I personally heard for the first time at was in 1997:

- We need consistency in Quality

- We need consistency in Supply

- We need this in Volume

Currently the greatest limiting factor to development of our industry is the lack of bird production and the lack of quality birds. Our aim at this conference is to develop a greater understanding of all aspects that cover the true science of livestock production as it applies to Ostrich, so that we can overcome this block in sustainable development of the industry.

All presentations at this conference interrelate to each other and cover production, processing and marketing from farm to consumer. To enable a greater understanding on how to achieve cost effective production on farm and assure a supply of birds producing quality products, the presentations this paper will focus on are the four phases that combined together make up “The Science of Livestock Production’:

Phase 1: Production Nutrition

Phase 2: Production Feed Management

Phase 3: Production Farm Management

Phase 4: Production Genetics

Production Nutrition

Over the past 20 – 30 years production nutrition has made very significant strides in livestock production. This need has been fuelled by the ‘price cost squeeze’ that forces producers to cut costs. As discussed in the paper on “Economics” some take the route to tackle the ‘price cost squeeze’ through looking at the ‘costs per tonne’ of feed and treating their livestock as ‘feed cost units’ and the successful tackle the problem through reducing the costs per ‘unit of production’ and treating their livestock as ‘Production Units’.

Production rations are designed with certain Production Goals in mind. Table 1 outlines these production goals. The Basics of Production Nutrition – Part 1 [1] details the components that make up rations that are required to meet the production goals required. We will discuss how to identify if your rations are likely to achieve the production goals as laid out in Table 1 and 2 of the “Economics” paper.

|

Production Group |

Production Goals |

|

Breeders off Season |

Replenishment of Lost Nutrient Reserves |

|

Breeders in Season |

Good Egg Production Adequate Nutrient Transfer to ensure strong healthy chicks at hatch. |

|

Baby Chicks O-2mths |

Smooth transfer from yolk sac absorption to external feed intake |

|

Grower Birds |

Optimum Growth Rates Optimum Feed Conversion Muscle Growth, Meat and Skin Quality (Slaughter Birds) Good Reproductive Organ Development (Future Breeders) |

|

Pre-Breeders |

Continued Reproductive Organ Development Early Puberty |

Whether mixing on farm, purchasing commercial rations or building a vertically integrated production operation with a common feed policy for quality control and consistency of end product – it is necessary to know if the rations you are working with are likely to meet these production goals. Production rations is a lot more than simply looking at the Protein levels and/or Energy levels that most use as a guide. As discussed in Basics of Production Rations [1] - Production rations will be balancing:

- Nutrient levels (Protein, Fat, Fibre, Vits, Mins etc)

- Levels and Ratios of Certain Amino Acids

- Nutrient Sources

- Ratios Ingredient Types (Grains, Forages, Protein etc)

- Ratios of Nutrients one to another

- Ratios of Inorganic and Organic Sources

- Ratios of Particle Sizes

In order to retain competitiveness nutritionists and animal feed companies committed to production will only publish certain guaranteed nutrient levels. The important levels that enable the commercial producer to assess the production characteristics of a ration are:

- Protein

- Fibre

- Fat

- Calcium

- Phosphorous

- Vitamin A

- Vitamin D

- Vitamin E

The other important information to assess the productive value of rations are the ingredients used in a ration. With the Ostrich’s limited daily intake and need for high nutrient levels, it is important that every ingredient in a Productive Ostrich ration has a positive influence in the rations. For example: Fibre is an essential component of a ration. Working with the correct fibre source such as Lucerne, many other nutrients are supplied from that fibre source. In contrast working with straw or hulls as a source of fibre provides not only very poor and indigestible fibre, but also very few additional nutrients making it impossible to find space in the ration for all the nutrients from other ingredient sources.

|

Ingredient Type |

Productive |

Use with Caution |

Non-Productive |

|

Forage |

Quality Lucerne Protein 17% Plus |

Grass, Poor Quality Lucerne 14% - 17% Lucerne |

Fresh Lucerne, Fresh Grass, Low Quality Lucerne |

|

Grains |

Maize |

Barley Wheat |

Oat, Milo/Sorghum, Rice, Rye |

|

Protein - Oil Seeds |

Dehulled Soya (Hi Pro) 47% Protein Soyameal 44% Protein |

Full Fat Soya |

Cottonseed, Canola, Rapeseed, Sunflower, Peanut, Lupins |

|

Animal Protein |

|

|

Fish Meal, Meat and Bone Meal, Carcass Meal. Any Protein from an Animal Source |

|

By-Products |

|

Wheat Middlings Distillers Dried Grains, What Bran, Corn Gluten Meal 60% |

Hulls and Husks, Corn Fractions, Mill Screenings, Brewers Dried Grains, Peanut Skins, Grape Residue, Mollasses, Hominy Chop, Citrus Pulp, Corn Gluten Feed 20%, Sugar Beet (whole, pulp or peelings) |

Commercial livestock farmers know that quality Lucerne, Maize and Soya are the best ingredients to use as the foundation for their rations and their stock just do better. In efforts to reduce costs the first course of action is generally to replace these ingredients with less expensive ingredients. The principal of productive rations is to include adequate levels of vitamins and minerals to enable the animal to achieve maximum utilisation of the nutrients in these ingredients. This is required to achieve increased performance to enable producers to reduce the cost per ‘Unit of production’. When added correctly the Vitamins and Minerals account for at least 50% of the performance characteristics of Production rations. In all the scientific papers currently published on Ostrich nutrition how often do you read any references to the Vitamins and/or the Minerals? The answer is almost never.

Table 2 is a summary of some ingredients found in livestock rations. As stated above most commercial livestock farmers know that productive rations should contain ingredients listed under ‘Productive’ Ingredients and productive Ostrich rations are exactly the same. The ingredients listed under ‘Use with Caution’ can be used with advantage in limited quantity. If any ingredients in the ‘Non-Productive’ column are included there will be some loss of production and depending on the amount and/or ingredient the loss of production can be severe and in some cases put the birds at risk. If working with commercial rations that state the ingredients as ‘collective terms’, it is very likely that many of the ingredients used are ingredients listed under ‘non-productive’ and some other non-productive ingredients that we see in livestock rations all too often.

Many companies producing commercial rations, unless committed to production, work to ‘least cost’ formulations and this policy generally result in changes of ingredients from batch to batch. Ostrich are very susceptible to ingredient changes and often go off feed when ingredients in a ration are changed from one batch to another. This is a double negative to productivity to be aware of. Not only are the rations lacking in production potential, when ostrich go off feed at best there will be a check in growth rate as a result of reduced feed intake. At worst a number of producers have reported bird losses as a direct result of birds going off feed following delivery of a new batch of feed.

In Summary:

Once the basics of production nutrition are understood and how they relate to Ostrich, many of the current difficulties relating to production are quickly understood. For production nutrition to be successful it must be matched with the Professional standards of Feed Management, Farm Management and Genetic Improvement programs.

Production Feed Management

Production Nutrition is about precision. Precision in ration design, ingredient selection, manufacture and the manner in which the feed is fed. The manufacture and the manner in which it is fed is the topic of this phase - Feed Management.

Feed Management falls into a number of sub-categories:

- Know what you are feeding

- Mix the Feed Accurately

- Weigh Everything Correctly

- Feed Management

- Water Management

- Stockmanship

- No Supplementation

All these areas have been documented in a number of articles and bulletins – the most recent Basics of Nutrition Part 2 [2] covers this in detail and also covers in detail a most important element of Feed Management – Understanding Feeding Rates.

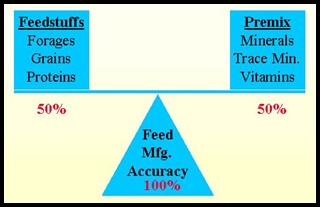

As referenced above 50% of the performance of Production rations comes from the vitamins and minerals in the rations (supplied by the premixes). Producers can have the most productive ingredients, the most carefully designed premixes and formulations but to be 100% successful the mixing must be done with absolute accuracy. Figure 1. Producers must remember at all times that in view of the Ostrich limited daily intake of feed, they do not tolerate mixing errors and most feed mills are not aware of this.

Figure 1 - Balancing Rations

There are many grazing birds on grass and/or Lucerne. There are a number of reasons given:

- It is cheaper

- It is more humane

- The birds are happier

- Told they should be grazed

When the true science of livestock nutrition and/or production is understood, there are a number of reasons that will make it clear that none of these reasons fit Ostrich, even when treating ostrich as ‘feed cost units’. When the science is understood, it will be clear that dependency on ‘grazed’ material as supplying part of the ration could be considered cruel unless there are extremely tight feed controls in place and a total understanding of all that is required to provide balancing rations for Ostrich. Ostrich are browsers not grazers. When feeding in the wild environment there is a diversity of plants and seeds for the birds to browse and when observed they select the plants with the highest nutrient content. This diversity is not available in the domestic environment as fields are generally grass or Lucerne.

The greater the attention to detail and understanding the bird’s responses to precision, the better the results and profitability producers will achieve.

Production Farm Management

There are many aspects to Farm Management that are an integral part of the overall science of livestock production. Some areas as they apply to Ostrich are:

- Bird Grouping/Management

- Pen Design and Layout

- Terrain Assessment

- Biosecurity Methods

- Water Quality

- Layout and Design for Feeding & Water

- Egg Handling Methods

- Record Keeping

- Incubation Facilities and Methods

- Chick Handling Facilities and Handling

- Stress Minimisation/Stockmanship

- Vaccination Programs & Disease Control

In the science of Livestock Production there is one element that is key to the success of any livestock operation at farm level. That is the influence of the ‘stockman’. This influence has been long recognised and well documented. As long ago as the 1950’s the influence of the stockman was clearly identified as a key element in Dairy production and could make a difference of as much as 400 gallons (1800 litres) per cow/year at a time when 1000 gallons (4400 litres) was at the top end of production. To put this into context – today top milk producers are achieving well in excess of 10000 litres per cow/annum.

Top of the list above is ‘bird grouping’. This applies to breeders as well as slaughter birds.

Breeders can be kept as pairs, trios, quads and colonies. The best stockmen will know which hens and males are mating with each other and in which nest the eggs are laid even when maintained as a colony. Keeping birds in colonies in areas in excess of 100hectares is very different to keeping birds in colonies in 1 hectare and 200 breeders have been reported kept in this manner. The latter was as a result of businessmen investing in the industry, seeing the birds as ‘production units’ but lacking experience in livestock production and the factors that influence production. The only way to be sure of genetics and exactly how the breeders are performing is to maintain the breeders in pairs and/or trios and maintain good records.

A further aspect that influences Breeder bird production is the characteristics of the Male. A good male will achieve significantly better egg production than a male with more domineering characteristics, as much as 40 eggs/hen in a season. In a production environment the stockman will have the instinct to identify the productive male from the aggressive male that upsets his/her hens. A good stockman has an empathy with the livestock in their care.

When raising slaughter birds from a business/production line viewpoint it makes sense to develop systems that have chicks moving from pen to pen on a regular basis through the production cycle from day old to final slaughter. Another common practice is moving birds at 3 months from rearers to growers. It is proven this does not work well for Ostrich and far better to develop systems of ‘batch in batch out’. It is well documented that ostrich stress easily. Moving from one pen to another is a stress situation for Ostrich. Whilst the birds generally keep eating there is a check in their feed conversion, and therefore growth rate, following each pen move and valuable time is lost in the growth period.

Excellent record keeping is an essential element of production livestock agriculture. It is the only way to identify correctly different management and genetic factors that influence performance.

Production Genetics

Over the past few decades there have been very significant improvements in the performance of the main livestock specie. For example:

· Broiler Chicken have reduced the growing period from 60 days to 42 days.

· Dairy Cattle yields increasing from 4,000 litres/cow/annum to in excess of 10,000 litres/cow/annum with controlled protein and butterfat levels. 80% reduction in incidence of mastitis and many other metabolic problems virtually eliminated.

· Egg laying in poultry now in excess of 310/hen/annum

· Hogs now finished in 92 days with controlled fat

· Livestock with carcass shape and size all controllable.

Farmers will have to decide on what basis they will be selecting birds. First it is important to recognise that there must be a feeding program in place that enables the effects of the poor nutritional programs bred out and the inherited traits of the birds to be achieved.

It should go without saying that every egg needs to be recorded by Breeder and provided a unique number and every bird on the farm requires identification from the moment of hatch. Extensive records must be kept and include:

In the Breeders:

· Egg Production

· Fertility

· Hatchability

· Infection

In the Progeny:

· Any Defects

· Feed Conversion

· Weight Gains

· Meat Yields/Conformation

o Muscle Size

o Percentage Primary to Secondary Muscles

· Hide Quality

o Quill cover

o Quill pattern

o Quill size

o Hair follicles and pinholes - to determine if these are genetic in origin and/or simply caused through management of the chicks and/or poor handling of the hide following slaughter.

As indicated in Table 3 the first few years of the selection program will need to be harsh.

|

Period |

Activity |

|

Year 1 |

Introduce Professional Levels of Nutrition Introduce Intensive levels of Feed and Farm Management Introduce Extensive Record Keeping |

|

End Yr 1 |

Cull Stock Introduce Fresh Genetics Utilise Records |

|

End Yr 2 |

Cull Stock Introduce Fresh Genetics Utilise Records |

|

Year 3 & 4 |

Continue same policy Utilise Records Start Grouping Offspring on Genetic Performance Basis |

|

Year 5 |

Commence Challenge Feeding Continue above Policy |

|

End Yr 5 |

Breeding Flock will achieve close to NEW OSTRICH INDUSTRY Target Averages. Continue with above Policy |

|

End Yr 8 |

The Offspring should far surpass current production targets |

|

Year 10 |

Extremely Cost Effective Meat Production with High Profit Potential |

There have been many extremely poor nutritional programs practiced on farms, most through ignorance of the long-term damage that this can cause. However, it must be remembered this leaves a legacy that in many cases is irreversible. For example insufficient levels of Vitamin E and/or Vitamin B1 for an extended period of time can lead to permanent sterility. There is clear evidence in recent years of birds reproductive organs reducing in size and late developing as a result of the poor levels of nutrition that have become the norm on many farms. In reverse…those farms that have introduced high standards of nutrition have seen a steady improvement in the production performance of their birds.

To aid producers and purchasers of breeder birds understand the influence of nutritional history on the production potential of the bird Blue Mountain introduced a Nutritional Classification system for our farmers to follow. Table 4

In the early years of a genetic improvement program it will be important to remember the nutritional influence as this can mask the high performing inherited genetic characteristics of the birds. The best genetic birds will always be the first to ‘crash’ when they are not nutritionally supported to match their potential levels of production. These types of birds are the first to become nutrient deficient in their efforts to support their inherited production potential.

|

Nutritional Classification System |

|

|

No BM Heritage |

|

|

Class 6 |

Birds

that have been fed according to the BM Program |

|

Class 5 |

Birds

that have been fed according to the BM Program |

|

Class 4 |

Breeder

Birds that have been raised on the BM Program from |

|

BM Heritage |

|

|

Class 3 |

Birds

that have been hatched from Class 5 or Class 6 |

|

Class 2 |

Birds

that have been hatched from Class 3 or Class 4 |

|

Class 1 |

Birds

that have been hatched from Class 1 or Class 2 |

As these same principals work in reverse with extended poor nutritional programs, the current breeder base is damaged and most breeders sold are either because the farm is failing or the breeders have not been performing. Therefore any farm starting out today I recommend purchase Day Old chicks from a number of different breeders. There has been little or no record keeping and purchasing from different breeders will provide a diversity of genetic material. Feed those chicks the best you can. It will then be possible to identify the better genetic chicks as they grow. Retain those as future breeders and slaughter the remainder. If raised correctly these chicks will start producing in their second season and the breeder herd can be developed along with good record keeping and hard culling to select the most productive lines.

Blue Mountain customers are developing a Superior Genetic Grading Program to enable the identification and grading of their breeders. This will evolve over the years as we achieve sufficient data for certain categories. The current categories are:

- Conformation

- Production

- Progeny Survival

- Progeny Meat Yield

- Progeny Skin Yield

There are a number of sub-categories within each category that are rated – for example:

Under Production the categories are:

- Egg Production

- Egg Quality

- Egg Weight

- Egg Fertility

- Egg Hatchability

Each category has a number of classes with the accumulative total of the classes in the different categories determining the final Grade for that Bird.

An example of the classes with in a category:

Egg Production:

Standard: Includes all whole eggs laid by hen, including those that are chipped, broken, mis-shaped or chalky in a 12 month laying season.

|

Class |

Number of Eggs |

|

Grade #1 |

100 or more |

|

Grade #2 |

85-99 |

|

Grade #3 |

70-84 |

|

Grade #4 |

55-69 |

|

Grade #5 |

40-54 |

|

Grade #6 |

Less than 40 |

At this time the influence of the Nutritional History cannot be over emphasised as a major inhibitor to the true genetic characteristics being identified. The paper Ostrich Genetics and Nutrition [3] discusses the reasons in detail.

Summary

To achieve commercial levels of Ostrich Production and ensure that the industry is economically viable, as can be seen Nutrition, Feed Management, Farm Management and Genetics all link together and interdependent on the other to achieve profitable production.

[1] Benson and Holle Nutritional Bulletin No. 83

[2] Benson and Holle Nutritional Bulletin No. 84

[3] Benson and Holle Nutritional Bulletin No. 87

Nutritional Bulletins are available at: Blue Mountain

Copyright© World Ostrich Association

HOME